Let’s take a closer look at an interesting question: Are shipping container walls load bearing? As you explore the concept of shipping containers being repurposed as living spaces or structures, it’s crucial to understand whether the walls of these containers hold significant weight. In this article, we will examine the structural integrity of shipping container walls, shedding light on whether they can bear loads and provide a secure foundation for various uses. So, let’s dive in and find out the answer!

Defining Load Bearing Walls

Understanding Load Bearing Walls

Load bearing walls are an integral element in building construction. These walls play a critical role in supporting the weight of the structure and transferring it to the foundation. They are responsible for maintaining the overall structural integrity of the building by distributing and supporting the vertical loads.

Key Characteristics of Load Bearing Walls

Load bearing walls possess several key characteristics that differentiate them from non-load bearing walls. They are generally thicker and sturdier, designed to withstand heavy loads and provide structural stability. These walls are strategically placed in a building’s layout to support the weight of the floors, roofs, and other elements above them. They are often built with specialized structural materials to enhance their load-bearing capacity.

Importance of Load Bearing Walls in Building Construction

Load bearing walls are essential in building construction for ensuring the safety and stability of the structure. They bear the weight of the building and distribute it evenly to the foundation, preventing structural failure. Additionally, load bearing walls determine the layout and design possibilities of a building. Understanding the load-bearing capacity of walls is crucial during renovations or when considering alterations to a building’s structure.

Structural Design of Shipping Containers

Overview of Shipping Container Structure

Shipping containers are renowned for their robust and durable design. The structure of a shipping container consists of a rigid frame welded to corner posts and reinforced by steel walls and flooring. These containers are designed to withstand external forces during transportation, but their load bearing capacity must be assessed before using them in construction projects.

Vertical Load Distribution in Shipping Containers

When used in building construction, shipping containers must bear significant vertical loads from the floors, roofs, and additional building elements. The vertical loads exerted on shipping containers are distributed through the corner posts and the container’s walls, which then transmit the forces to the container’s foundation. Understanding how these loads are distributed is crucial for ensuring the structural integrity of shipping container buildings.

Understanding Wall Strength and Load Bearing Capacity

The strength and load bearing capacity of shipping container walls depend on various factors, including the thickness and quality of the steel used. The vertical load distribution and the presence of any structural modifications can also affect the load bearing capacity. Assessing wall strength and load bearing capacity is essential to determine the suitability of shipping containers for specific construction purposes.

Evaluation of Shipping Container Walls

Materials and Construction of Shipping Container Walls

Shipping container walls are constructed using robust and durable materials, typically high-grade steel. The steel walls are corrugated, providing added strength and resistance to external forces. The precise construction and material quality of shipping container walls contribute significantly to their load-bearing capability.

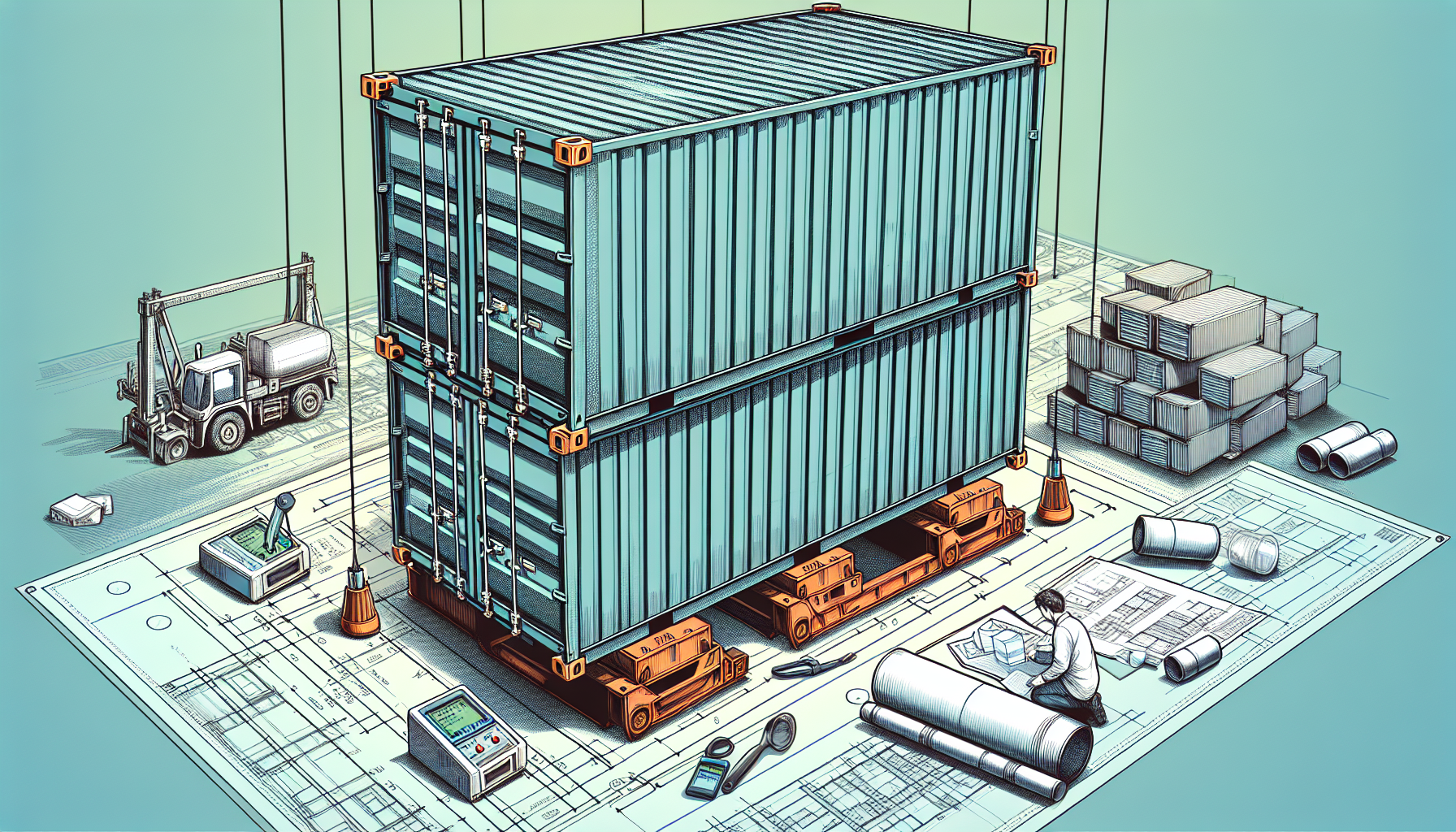

Assessing Load Bearing Capability of Shipping Containers

Before utilizing shipping containers in construction projects, it is crucial to assess their load-bearing capacity. This involves evaluating the container’s structural design, including its walls, floor, and roof, to determine if it can withstand the intended vertical loads. Consulting with structural engineers and conducting load tests can provide valuable insights into whether a shipping container is suitable for load-bearing purposes.

Factors Affecting Load Bearing Capacity

Several factors can influence the load-bearing capacity of shipping container walls. These include the thickness and quality of the steel used, the container’s structural modifications, and the distribution of vertical loads. Understanding these factors is essential for accurately assessing the load-bearing capability of shipping containers and ensuring their safe and reliable use in building construction.

Certification and Testing Standards

ISO Standards for Shipping Containers

The International Organization for Standardization (ISO) has developed standards specifically for shipping containers. These standards cover various aspects, including dimensions, strength, and structural integrity. Adhering to ISO standards ensures that shipping containers meet specific quality criteria, providing reassurance regarding their load-bearing capabilities.

Certification Process for Load Bearing Containers

Certification processes for load bearing containers involve rigorous testing and evaluation to determine their structural strength. Independent organizations provide certifications based on stringent criteria and testing methods. Obtaining certifications ensures that shipping containers meet the necessary requirements for load-bearing applications and adhere to recognized standards.

Testing Methods and Criteria

Load testing is an essential component of evaluating the load-bearing capacity of shipping containers. Various testing methods, such as static and dynamic tests, are used to simulate real-world loads and assess the structural integrity of containers. These tests consider factors like load distribution, deflection limits, and ultimate strength to comprehensively evaluate a shipping container’s load-bearing capability.

Structural Modifications to Shipping Containers

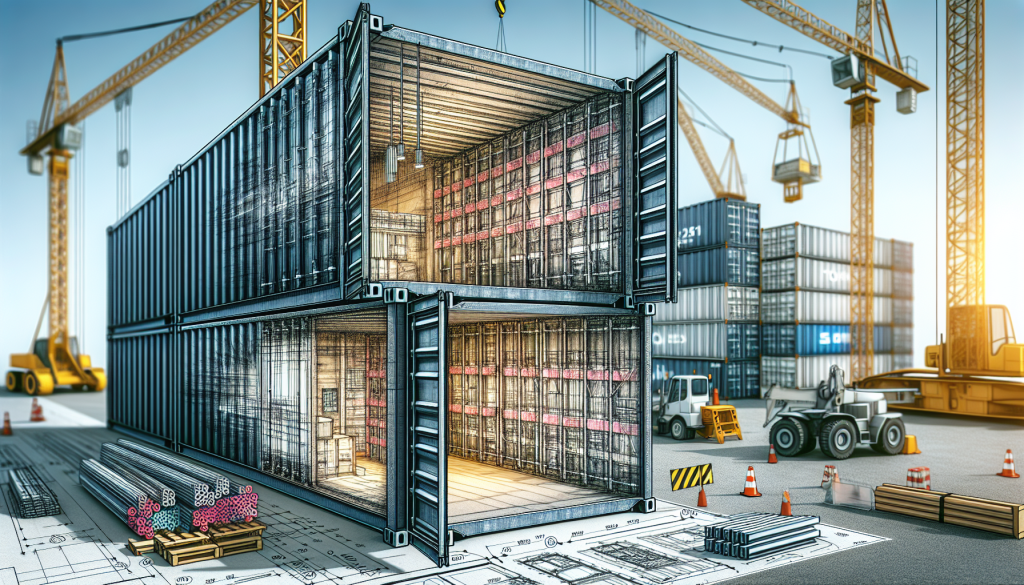

Container Alterations and Their Impact on Load Bearing

Structural modifications to shipping containers are common in building construction projects. These alterations can include removing sections of walls, adding windows or doors, or joining containers together. It is crucial to consider the potential impact these modifications may have on the load-bearing capacity of the containers. Proper planning and engineering expertise are essential to ensure that any modifications maintain or enhance the load-bearing capability of the containers.

Permissible Structural Modifications

Not all structural modifications are suitable for shipping containers used as load-bearing elements. It is important to consult with qualified professionals to determine permissible modifications that maintain or improve the structural integrity of the container. Permissible alterations may include the addition of reinforcement elements, such as steel beams or columns, to augment the load-bearing capacity.

Reinforcing Shipping Container Walls

Reinforcing shipping container walls can enhance their load-bearing capabilities. This can be achieved through strategic placement of additional structural elements, such as steel columns or beams, to provide extra support. Reinforcing shipping container walls must be done carefully and in coordination with engineers to ensure the overall structural integrity of the container.

Use Cases and Limitations

Common Applications of Shipping Container Buildings

Shipping container buildings have gained popularity due to their versatility and cost-effectiveness. They are utilized in various applications, such as residential dwellings, offices, retail spaces, and even emergency shelters. Their modular nature allows for quick assembly and portability, making them ideal for temporary or permanent structures.

Load Bearing Considerations for Various Uses

When using shipping containers as load-bearing elements, it is essential to consider the specific requirements and loads associated with each application. Residential buildings may have different load-bearing needs compared to commercial or industrial structures. Understanding the intended use and load requirements is crucial for ensuring that shipping containers can safely support the designated loads.

Limitations and Potential Challenges

While shipping container buildings offer numerous benefits, they also have limitations and potential challenges. The load-bearing capacity, for instance, may be limited compared to traditional building materials. Additionally, modifications and alterations to shipping containers may require additional costs and planning to ensure compliance with building codes. Understanding these limitations and challenges is essential for making informed decisions when considering shipping containers for load-bearing purposes.

Regulations and Building Codes

Compliance with Local Building Regulations

Shipping container buildings must comply with local building regulations to ensure safety, structural integrity, and legal compliance. These regulations may include requirements for load-bearing capacity, fire safety, insulation, and other relevant aspects. It is essential to consult with local authorities and obtain necessary permits to ensure compliance with building codes and regulations.

Adhering to International Building Codes

In addition to local regulations, international building codes provide guidance and standards for incorporating shipping containers into the construction industry. Following international building codes ensures consistency and a high standard of safety across various regions and jurisdictions. It is important to consider both local and international codes when utilizing shipping containers as load-bearing elements.

Building Permits and Inspections

Obtaining building permits is a crucial step in ensuring compliance with regulations and codes when utilizing shipping containers as load-bearing walls. Building permits typically require detailed plans, engineering calculations, and inspections during and after construction. These permits and inspections help ensure that load-bearing walls meet the necessary standards, further enhancing the safety and structural integrity of the overall building.

Professional Expertise and Guidance

Architects and Engineers for Container Structures

Architects and structural engineers play a vital role in designing and implementing shipping container structures. Their expertise helps ensure that load-bearing walls are appropriately incorporated into the overall building design. Experienced professionals can provide valuable insight into load-bearing considerations, material selection, and modification possibilities, helping optimize the use of shipping containers in construction projects.

Consulting Specialists in Container Construction

The field of container construction involves unique challenges and considerations. Consulting with specialists who have experience in container construction can provide valuable guidance specific to load-bearing walls. These specialists understand the intricacies and potential risks associated with shipping container structures, ensuring that load-bearing walls are designed and implemented safely and effectively.

Seeking Professional Advice

When considering shipping containers as load-bearing walls, it is recommended to seek professional advice from architects, structural engineers, and consultants experienced in container construction. These professionals can assess the specific requirements of a project, provide expert recommendations, and ensure that all necessary regulations and standards are met. Seeking professional advice minimizes the risks associated with load-bearing wall design and ensures optimal structural integrity.

Safety and Structural Integrity

Ensuring Safe Load Bearing Walls

Safety is paramount when utilizing shipping containers as load-bearing walls. Ensuring that the walls are designed and constructed to safely bear the intended loads is crucial. Proper engineering calculations, adherence to regulations, and material selection are key factors in ensuring the safety of load-bearing walls. Regular inspections and maintenance are also essential to identify and address any potential issues before they compromise the structural integrity.

Regular Inspections and Maintenance

Periodic inspections and maintenance are critical to preserve the safety and longevity of load-bearing walls. These inspections should encompass visual assessments, structural integrity checks, and identification of any signs of damage or deterioration. Maintaining load-bearing walls includes addressing any issues promptly, such as repairing corrosion or reinforcing weak areas, to prevent structural failures.

Mitigating Risks and Ensuring Longevity

Mitigating risks associated with load-bearing walls involves proactive measures throughout the construction process. Following standards and regulations, using qualified professionals, and employing suitable construction techniques help ensure the longevity and structural integrity of shipping container walls. Regular monitoring, inspections, and maintenance, combined with proper load management, further enhance the safety and reliability of load-bearing walls throughout their lifespan.

Future Innovations and Advancements

Research and Development in Container Construction

Container construction continues to evolve and advance through ongoing research and development efforts. Researchers are exploring innovative techniques and materials to enhance the load-bearing capacity of shipping container walls. Collaboration between industry professionals, engineers, and architects contributes to the development of new and improved solutions that further expand the possibilities of container construction.

Enhancing Load Bearing Capabilities

As technology and engineering knowledge advance, the load-bearing capabilities of shipping container walls are anticipated to improve. Innovations in material science, structural design, and fabrication techniques may lead to stronger and more efficient load-bearing walls. These advancements will offer greater flexibility in design and construction, ensuring that shipping containers continue to be a viable option for load-bearing applications.

Sustainability and Eco-Friendly Solutions

The future of load-bearing shipping container walls also includes a focus on sustainability and eco-friendly solutions. Researchers are exploring ways to repurpose used containers, reduce waste, and improve energy efficiency. By incorporating sustainable materials, insulation, and green technologies, shipping container buildings can contribute to a more environmentally conscious construction industry.

In conclusion, shipping container walls can indeed be load bearing, but it is crucial to assess their load-bearing capacity and consider various factors such as construction materials, modifications, and compliance with regulations. Understanding load-bearing requirements, consulting professionals, and performing regular inspections and maintenance are key to ensuring the safety and structural integrity of shipping container buildings. With ongoing research and development, the future holds exciting possibilities for enhanced load-bearing capabilities and sustainable solutions in container construction.

I am James, the creator behind SeaBoxInnovations.com. Welcome to our premier online destination dedicated to the world of sea containers. Think Inside the Box is our tagline, and our website is your go-to source for exploring the endless potential of these versatile and adaptable containers. Whether you’re interested in purchasing, customizing, or learning about the latest trends in container architecture and design, we have you covered. Join us as we bridge the gap between traditional uses and cutting-edge applications, promoting sustainability and innovation in design and construction. Get ready to embark on your next big project with SeaBoxInnovations.com.